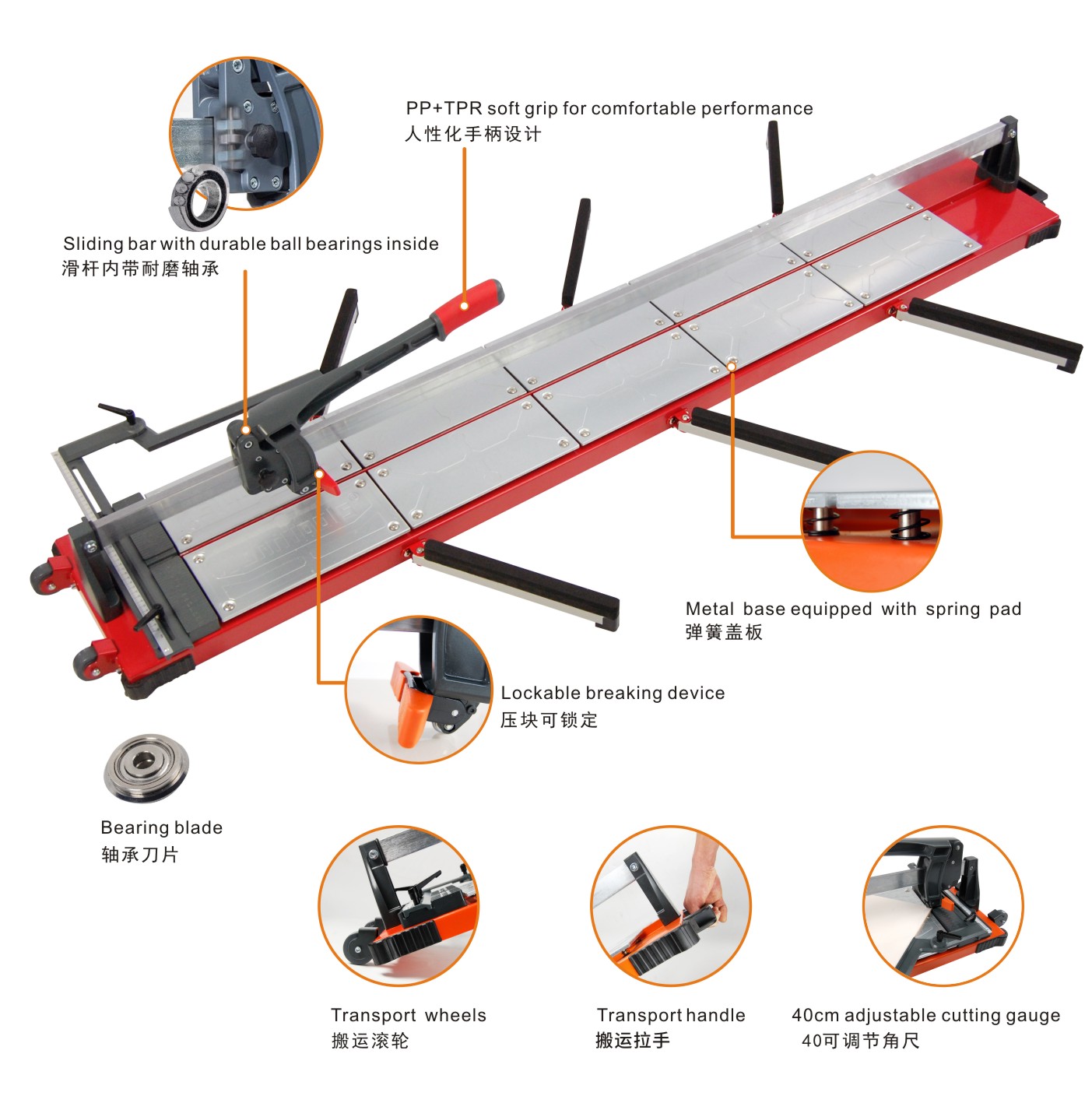

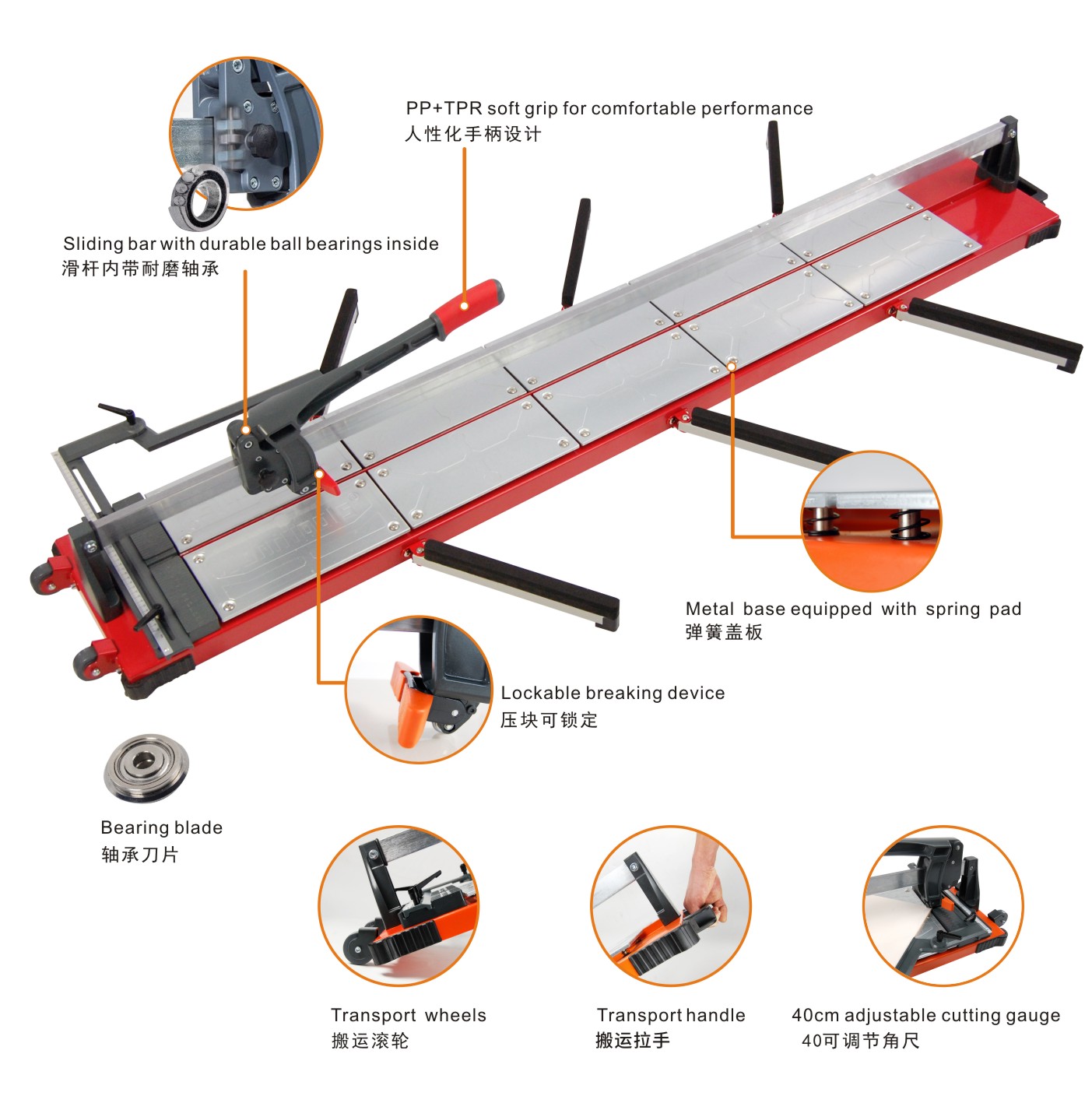

* Max. working length: 1650mm * Max. cutting tile thickness:16mm

*Metal structure base equipped with spring pad,excellent cutting experience with the elastic force

* Human-engineering big handle,PP+TPR soft grip for comfortable performance

* Sliding bar with durable ball bearings for smooth scoring on large tiles

* Lockable breaking device provides optimal view during cutting

* Extension arms provide extra stability for larger, heavier tiles

* Coated tungsten-carbide cutting wheel with bearings for smooth and durable scoring

* Multipurpose cutter for most tile including ceramic , porcelain, mosaics etc.

Direction for use

RIP CUT

1.Place the tile at the front edge against the front stop

2.Position the tile so the line of cut is directly over the scoring line,which is the line between the left and right pad.

3.Place the extension arms under the tile for the best possible support

4.Adjust the cutting guide by loosening the gauge and sliding it left or right to the desired cutting position,and lock the gauge

in place

MAKING THE CUT

1.Place the cutting wheel on the rear edge of the tile.

2.Slide the wheel forward by pushing the handle down with medium pressure,

scoring the tile surface glaze as the handle is pushed forward.

DIAGONAL CUT

The gauge can also assist in making diagonal cuts.

First loosen the gauge so it can move side to side to adjust to the size of the tile you are cutting. Then loosen the knob on the

angle guide dial to allow the tile to rest against the angle guide ,when the tile is positioned for a diagonal cut.

Tighten both knobs ,you are now ready to make the diagonal cut.

NOTE

It is important to make one continuous motion.scoring the surface only once per tile .

After scoring ,and without moving the tile ,position the handle so that the breaker bar is slightly in from the front edge of the

tile and front stop.

Apply increasing pressure on the handle until the tile snaps along the score line.